Deburring cleaning machine has been used in mechanical deburring processing. No matter what kind of precision workpiece is in the process of turning and milling, there are many burrs on the workpiece. The existence of burrs will inevitably affect the finishing process and the quality of the product. Therefore, residual burrs are never allowed in the finished product.

In the process of mechanical deburring, according to different processing requirements and processing conditions, according to the shape and size of the parts, the size of the burr is also different, and the requirements for deburring and polishing are also different. Generally speaking, the requirements for deburring cleaning machines are different. The choice of abrasive is critical.

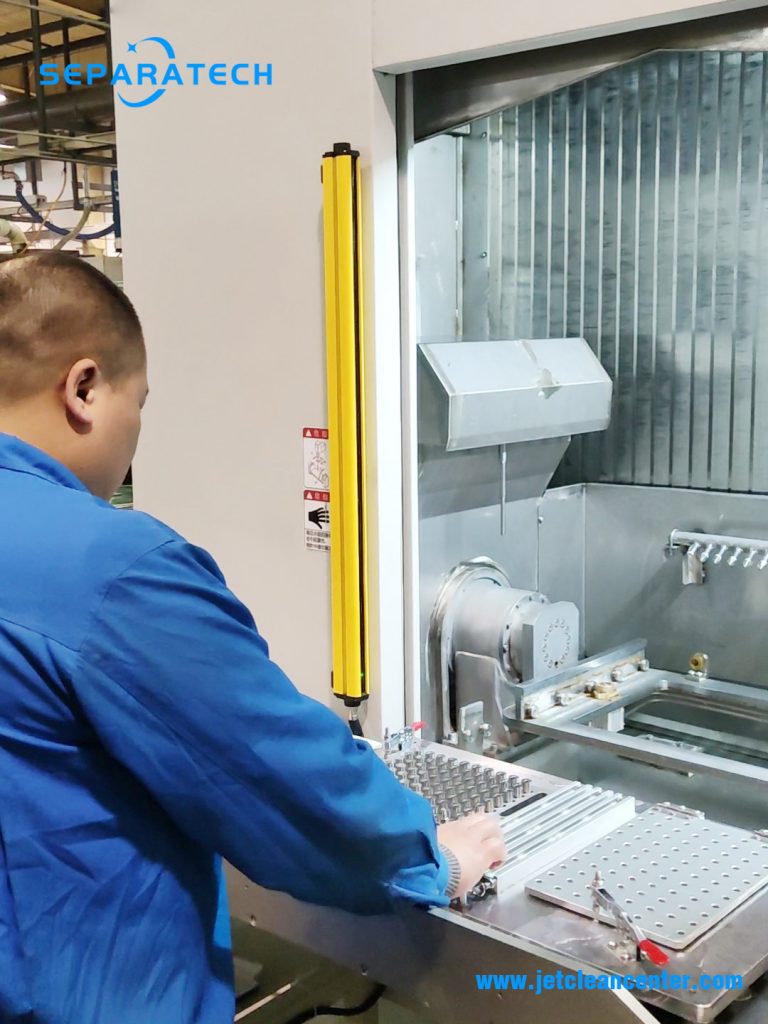

The deburring cleaning machine uses a new magnetic field technology, which uses magnetic force and stainless steel needles (abrasive semi-permanent) to collide and rub against the workpiece to achieve deburring, brightening, polishing and other effects. Fully grind the workpiece from multiple angles, so as to achieve multiple effects such as deburring, polishing, and cleaning. Magnetic cleaning machines can polish workpieces in large quantities. After the polishing is completed, the CNC high-pressure cleaner (dual-shaft mini-machine) can separate the steel needles from the sieve, which greatly improves the work efficiency.

The deburring cleaning machine equipment and the size of the abrasive used can be customized according to customer requirements, and the appropriate model and abrasive can be selected according to the size of the workpiece to achieve the best results.

The deburring cleaning machine is widely used in various industries and is suitable for: aviation, metallurgy, copper, electronic communication, automobile industry, etc.