What are High-Pressure Deburring and Washing machine?

High-Pressure Deburring and Washing machine is system that use water jets at very high pressures (up to 10,000 PSI or 75 MPa) to remove burrs, chips, and other contaminants from various workpieces. Burrs are unwanted protrusions or rough edges that result from machining processes such as drilling, milling, or cutting. They can affect the quality, functionality, and safety of the parts, as well as cause problems for downstream operations such as assembly or coating. Chips are small pieces of metal or plastic that are detached from the workpiece during machining. They can also interfere with the performance and appearance of the parts, as well as damage the tools or equipment.

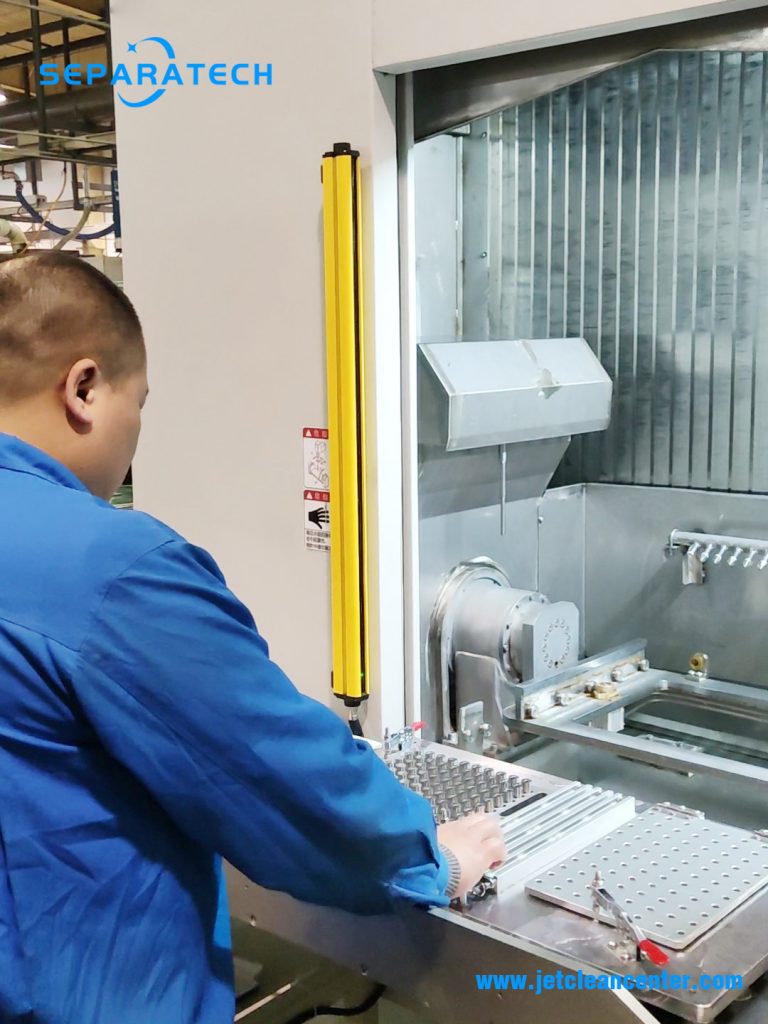

High-Pressure Deburring and Washing machines use water as a liquid tool to deliver precise and powerful cleaning energy to the part surface. The water jets can be directed by fixed nozzles, rotating spray heads, or robotic arms to reach every corner and hole of the workpiece. The water jets can also be adjusted in pressure, flow rate, temperature, and angle to suit different materials and applications. The water can also be mixed with detergents or additives to enhance the cleaning effect.

What is deburring and why is it important?

Deburring is the process of removing unwanted material from the edges or surfaces of metal parts that are produced by machining, casting, forging or other methods. These unwanted material can be burrs, chips, flashings or other defects that can affect the quality, functionality and safety of the parts. For example, burrs can cause scratches, corrosion, leakage, interference or injuries. Therefore, deburring is an essential step in the manufacturing process to ensure the parts meet the required specifications and standards.

How does high-pressure deburring and washing work?

High-pressure deburring and washing machines use water jets at pressures up to 10,000 PSI (or 75 MPa) to remove burrs, chips and flashings from metal parts. The water jets are directed to the part surface by fixed nozzles, rotating spray heads or robotic arms that can reach hard-to-access areas such as cross holes, deep holes or tap holes. The water jets act as liquid tools that can cut through the unwanted material without damaging the part or affecting its dimensions. The high-pressure water also cleans the part from dirt, oil, grease or other contaminants that may be present on the surface.

What are the benefits of High-Pressure Deburring and Washing machine?

High-Pressure Deburring and Washing machine offer many advantages over traditional methods of deburring and cleaning, such as manual labor, mechanical tools, abrasives, chemicals, or ultrasonic waves. Some of the benefits are:

– Efficiency: High-Pressure Deburring and Washing machines can perform both deburring and cleaning in one step, reducing cycle time and labor costs. They can also handle complex geometries and hard-to-reach areas that are difficult or impossible for other methods.

– Quality: High-Pressure Deburring and Washing machines can remove burrs and chips without damaging or altering the part surface, preserving the dimensional accuracy and surface finish of the workpiece. They can also remove other contaminants such as oil, grease, dust, or rust that may affect the quality or appearance of the part.

– Safety: High-Pressure Deburring and Washing machines can eliminate the risk of injury or infection from sharp burrs or chips that may cut or puncture the skin of workers or customers. They can also reduce the exposure to hazardous chemicals or solvents that may cause health or environmental problems.

– Sustainability: High-Pressure Deburring and Washing machines can reduce the waste generation and energy consumption of deburring and cleaning processes. They can also recycle the water used in the system by filtering and reusing it for multiple cycles.